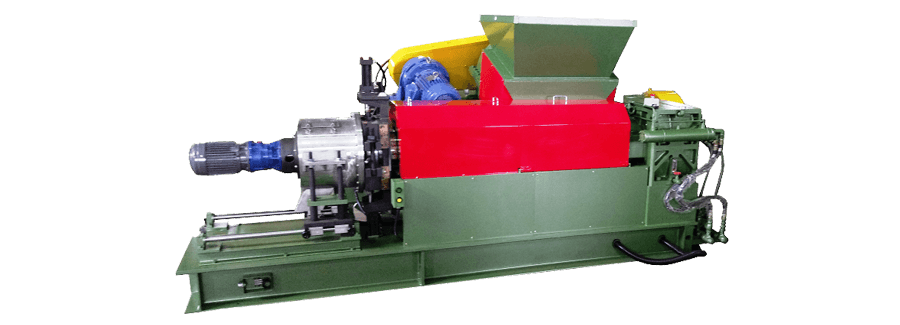

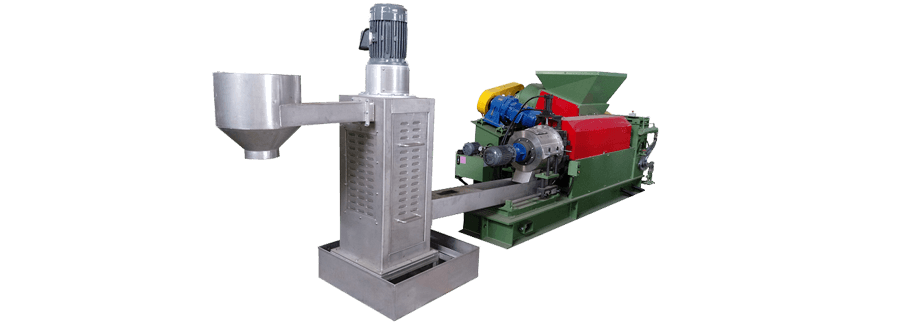

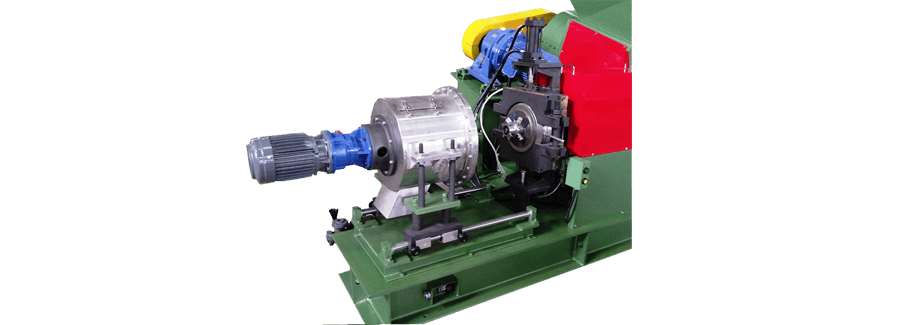

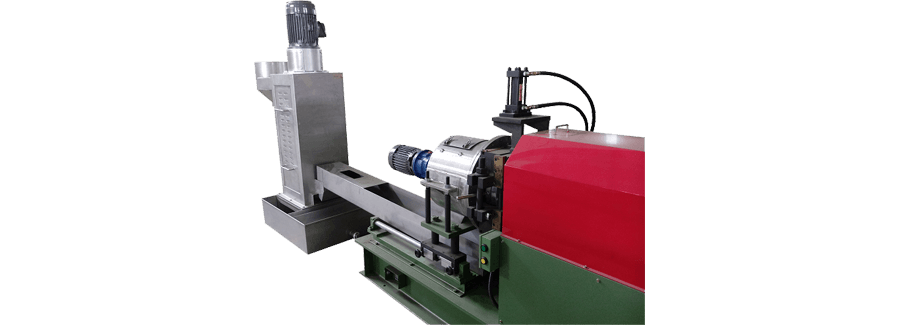

Feeder-Ruder Pellet Making Extruder

Extrusion & Pelletizing for Rubber, Plastic, Chemical Industries

|

Model |

Feeder power |

Feeder R.P.M. |

Hopper Capa. |

Extruder Dia. |

Extruder power |

Extruder R.P.M. |

Pellet cut power |

KD-FR-50 |

3 HP |

0 – 20 |

50 Liter |

50 mm |

10 HP |

0 - 50 |

1/2 HP |

KD-FR-75 |

3 HP |

0 – 20 |

50 Liter |

75 mm |

15 HP |

0 - 50 |

1 HP |

|

KD-FR-100 |

5 HP |

0 – 20 |

100 Liter |

100 mm |

20 HP |

0 - 50 |

1 HP |

|

KD-FR-125 |

7.5 HP |

0 – 20 |

150 Liter |

125 mm |

50 HP |

0 - 50 |

2 HP |

|

KD-FR-160 |

10 HP |

0 – 20 |

200 Liter |

160 mm |

75 HP |

0 - 50 |

2 HP |

|

KD-FR-180 |

10/15 HP |

0 – 20 |

250 Liter |

180 mm |

100/125 HP |

0 - 50 |

3 HP |

|

KD-FR-200 |

15/20 HP |

0 – 20 |

250 Liter |

200 mm |

125/150 HP |

0 - 50 |

3 HP |

|

KD-FR-250 |

25/30 HP |

0 – 20 |

350 Liter |

250 mm |

150/200 HP |

0 - 50 |

5 HP |